DJI AGRAS T16

Optimized Power. Unrivaled Performance.

The Agras T16 has an improved overall structure with modular design and supports the highest payload and widest spray width ever in a DJI agricultural drone. With powerful hardware, an AI engine, and 3D-operation planning, the T16 brings operation efficiency to a whole new level.

- 16L Spray Tank

- Metal Cased Battery

- Modular Quick Folding Design

- DBF Imaging Radar & Obstacle Avoidance

- RTK Centimeter Level Accuracy

- Can operate at night

- LED Lighting

- 20L Seeds Spreading System

The updates on all technology fronts when compared to the already successful Agras MG-1P are remarkable!

Efficient and Intelligent Solutions

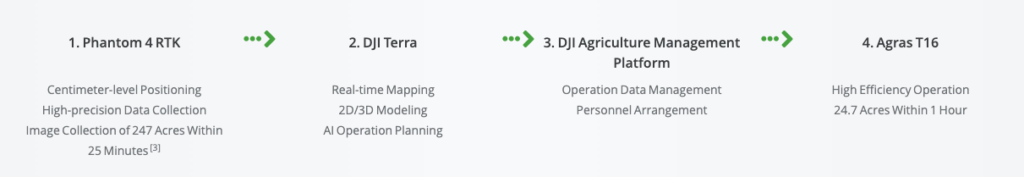

Low production and time-consuming operations are now a thing of the past. DJI’s advanced equipment and integrated agriculture management system provide intelligent data collection and analysis, applicable for field planning, crop inspection, and insect and pest control.

Crop Protection

T16

The T16 can be used for insects and weed control for a variety of crops such as rice, wheat, corn, citrus trees, cotton, and much more.

Revolutionized Structure. Reliable Operation.

The all-new modular design of the T16 simplifies assembly and accelerates daily maintenance. An IP67 rating provides reliable protection for key components of the drone. A light, yet durable airframe is made of carbon fiber composites and can be quickly folded to 25% of its original size, making it easy for transportation. Both the battery and spray tank are easily swappable, significantly improving the efficiency of power and liquid supply.

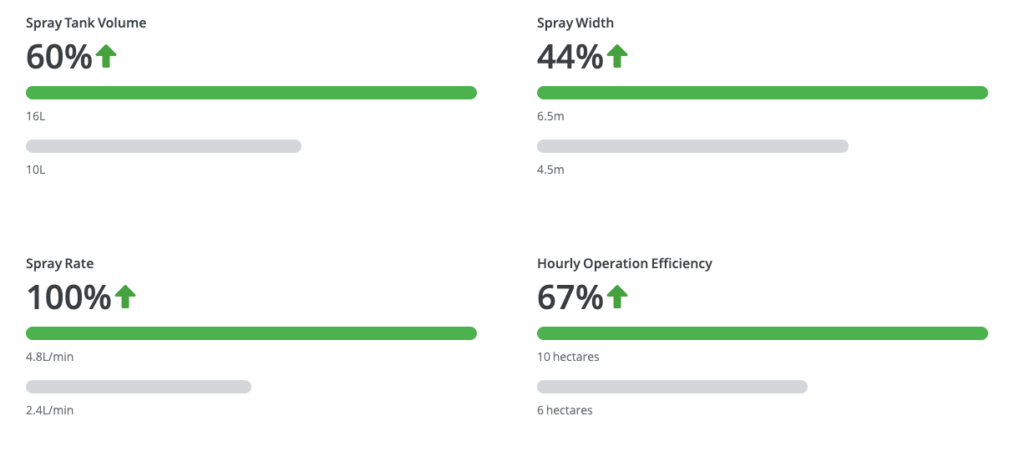

Higher Payload. Enhanced Efficiency.

Supported by its outstanding flight performance, the T16 spray tank can carry up to 16 L, and the spray width has increased to 6.5 m. The spraying system has 4 delivery pumps and 8 sprinklers with a maximum spray rate of 4.8 L/min. The T16 can spray 24.7 acres (10 hectares) [1] per hour. The spraying system also has an all-new electromagnetic flow meter, providing higher precision and stability than conventional flow meters.

Powerful System. Increased Safety.

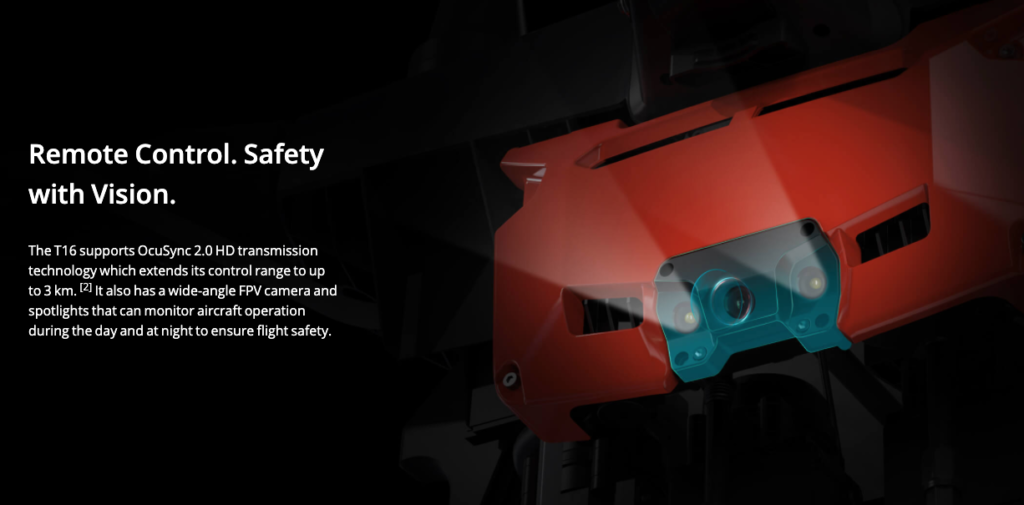

The all-new modular aerial-electronics system in the T16 has dual IMUs and barometers and adopts a propulsion signal redundancy design to ensure flight safety. The GNSS+RTK dual-redundancy system supports centimeter-level positioning. It also supports dual-antenna technology that provides strong resistance against magnetic interference.

Upgraded Radar. Easier Operation.

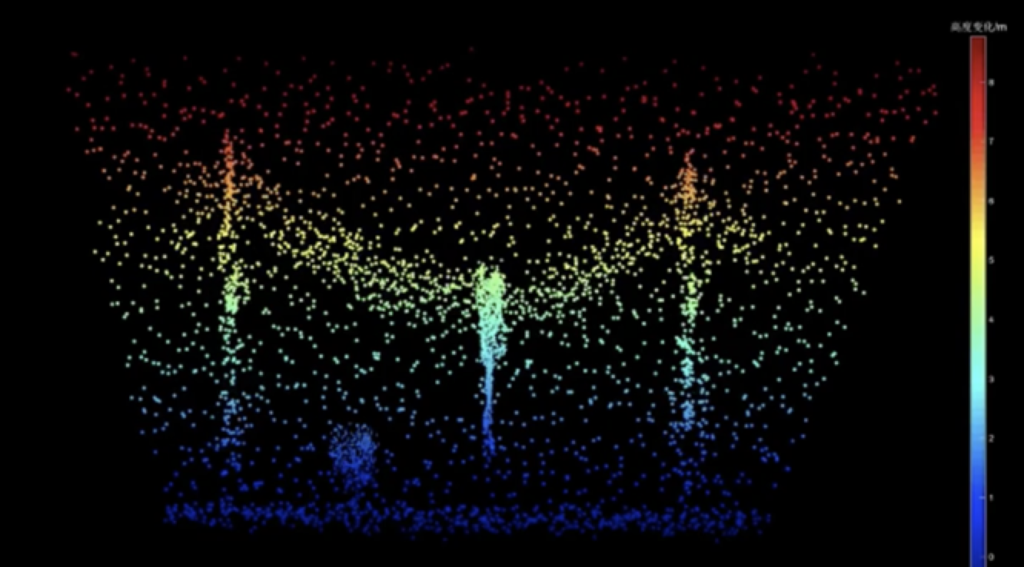

The T16’s upgraded radar system can sense the operating environment during the day or at night, without being affected by light or dust. It has greatly improved flight safety with forward and backward obstacle avoidance and a horizontal FOV (field of view) of 100°, double that of previous DJI agricultural drones. It can also detect the angle of a slope and adjust to it automatically even in mountainous terrain. This innovative radar system adopts Digital Beam Forming (DBF) technology, which supports 3D point cloud imaging that effectively senses the environment and helps to circumvent obstacles.

DBF Imaging Radar: 3D Point Cloud Imaging

Different Needs. Different Modes.

The T16 provides different modes for flat ground, mountains, and orchards, to meet most operational needs. Up to five T16 aircraft can be controlled by a single T16 remote controller simultaneously, doubling the efficiency of single-pilot operation.

Mountains

An outstanding propulsion system and slope angle detection technology make it easy to operate in mountainous terrain.

Orchards

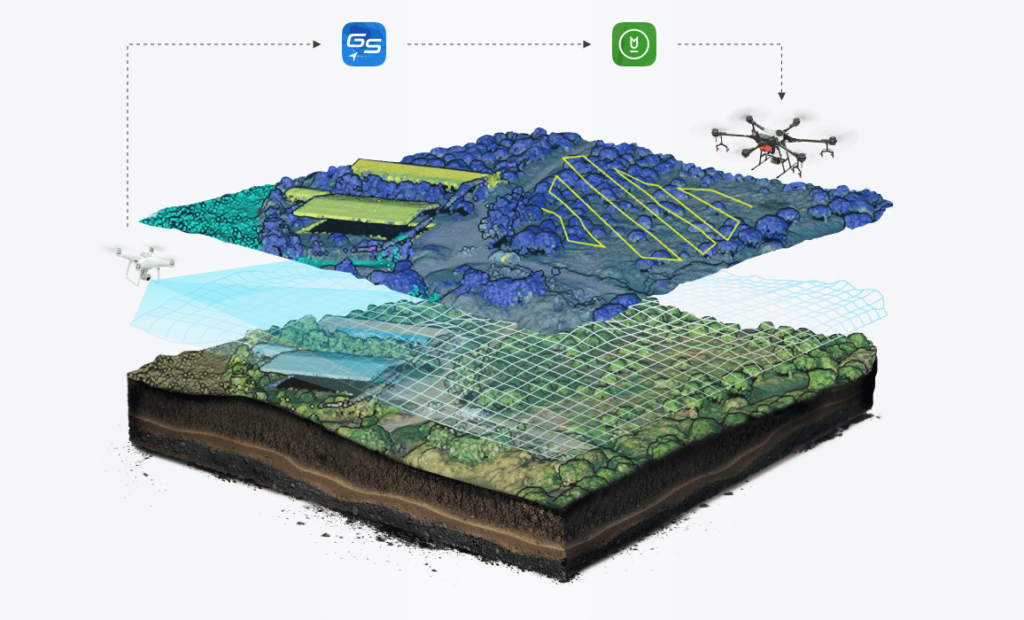

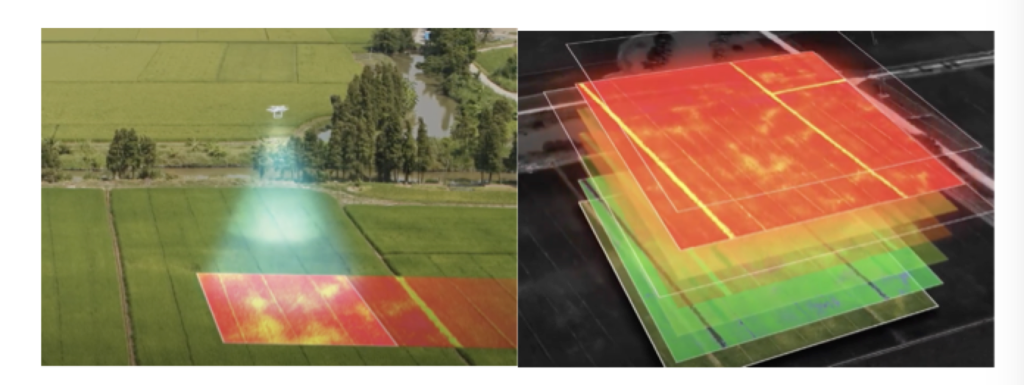

Use the T16 with DJI Terra to build a 3D model of the operation area and identify fruit trees with AI technology. Then, create 3D operation plans according to tree distribution and altitude.

Flat Ground

Manual Operation Mode, A-B Route Operation Mode, and Route Operation Mode are available to cover most operational needs.

The difference between drone spraying and traditional spraying on orchard

Traditional spray application techniques require excessive amounts of pesticides to effectively control pests and diseases.

The DJI agriculture spraying drone system used in the aerial and the entire process is automatic, through accurate positioning of farmland or fruit trees, the performance of AI identification, spraying height determination function, variable-rate, and more Rotor air-assisted, low-altitude, and low-volume precision spray effectively achieved the digital and science management of agriculture.

The DJI agricultural UAV AI recognition system can quickly recognize the structure and type of fruit trees and their size, shape, and density of branches and leaves, and apply the correct amount of pesticides in real-time.

The intelligent calculation of DJI Agras T16 can save your pesticide cost. Low-altitude and small-volume spraying technology achieves uniform pesticide deposition, high pesticide utilization rate, and can save 30-50% of pesticide dosage on average. The water consumption of Agras T16 is 1.28-4.8L/acre. Compared with the water consumption of tractor spraying, each acre reaches 30-40L. It saves a lot of water.

For diseased fruit trees, the DJI spraying drone can do a single hovering and spraying operation. Fruit trees that need to be sprayed are sprayed, and fruit trees that do not need to be sprayed are automatically not sprayed.

Comprehensive Solution. Intelligent Operation.

DJI Agriculture is committed to making the workflow of crop protection more efficient and intelligent. With drones and effective tools, DJI’s agriculture solution greatly simplifies operations, improves efficiency, and increases industrial upgrades.

T Spreading System 2.0

The T-Series Spreading System is compatible with the DJI Agras T16 or T20 aircraft. It offers efficient, reliable and stable spreading operations when dispensing dry material of a diameter between1mm to 10mm . The material delivery rate is accurately controlled by the built-in stirring device and the hopper gate. Use the DJI T16 app to set parameters such as hopper outlet size and spinner disk rotating speed. The app also provides information such as empty tank warning and abnormalities in disk speed, temperature, and hopper outlet size.

Note: Please allow 8 weeks to ship if not in stock

SPECIFICATIONS

- Weight: 2.1 kg (excluding the optional fender)

- Hopper Volume: 20 L

- Hopper Maximum Load: 16 kg (T16 and T20 Japan Version), and 20 kg (T20 version)

- Material Diameter: 0.5 mm to 5 mm (0.02″ to 0.20″)

- Max. Hopper Outlet Area: 32.3 cm2

- Optimal Spreading Range: 5 m to 7 m

USAGE FOR SPREADING SYSTEM 2.0

- For 45 kg/ha of material spread.

- Adjust hopper outlet size to 8 kg/min.

- Adjust spreading range to 5 to 7 meters.

- Set flight speed to 5 m/s.

IN THE BOX

- Spreading Hopper (1)

- Spinner Disk (2 Spare)

- M4 Screw (2)

2600W 4-Channel Intelligent Battery Charger

Up to four batteries can be charged simultaneously. When using the single-channel quick charging mode, a full charge only takes 20 minutes, a 50% increase in speed from the previous generation. The charger has a built-in battery health management system that monitors critical data in real time, such as voltage and temperature, to ensure charging safety.

T16 Intelligent Flight Battery

The T16 Intelligent Flight Battery has a capacity of 17,500 mAh and a 14S high voltage system that reduces power consumption. It is designed with an IP54-rated all-metal housing, and heat dissipation efficiency has increased by 140% from the previous generation. Supported by cell-balancing technology, the battery has an increased charging cycle of up to 400, [4] 100% higher than the previous generation, significantly reducing operating costs.

Agras T16

1.What are the flight capabilities of the T16?

The T16 has a maximum flight altitude of 30 m.

The maximum communication distance is 3 km when measured at a flight altitude of 2.5 m.

The maximum flight speed is 10 m/s, and the maximum operational flight speed is 7 m/s.

Additionally, the T16 can hover for 18 minutes when weighing 24.5 kg during takeoff, and for 10 minutes when weighing 39.5kg.

2.How much area can the T16 cover per hour?

The T16 can spray up to 10 hectares per hour (24.7 acres) with a spray width of 6.5 m, a speed of 6 m/s, and an altitude of 2 m.

3.What are the advantages of the T16 compared to the MG-1P series?

The T16 is equipped with a heavier payload, increased spray width, and enhanced efficiency.

Moreover, its modular design allows for a fast change of the battery and spray tank.

Its core module has an Ingress Protection rating of IP67, and the T16 has a host of features such as Digital Beam Forming (DBF) Imaging Radar, Active Obstacle Circumvention, AI recognizing, and an Orchard Mode.

4.What directions do the propellers of the T16 rotate?

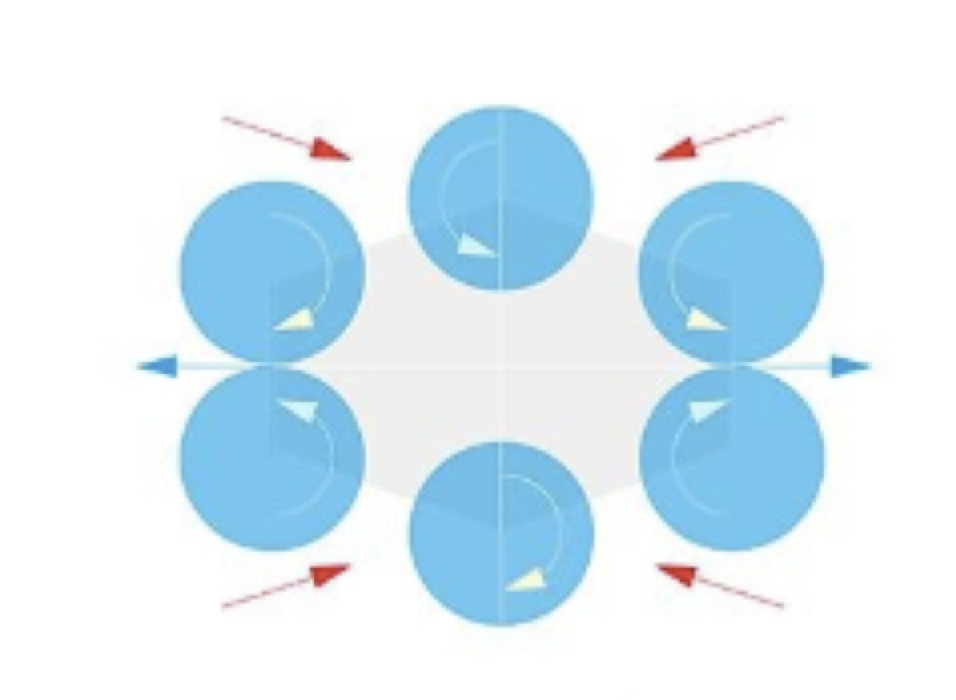

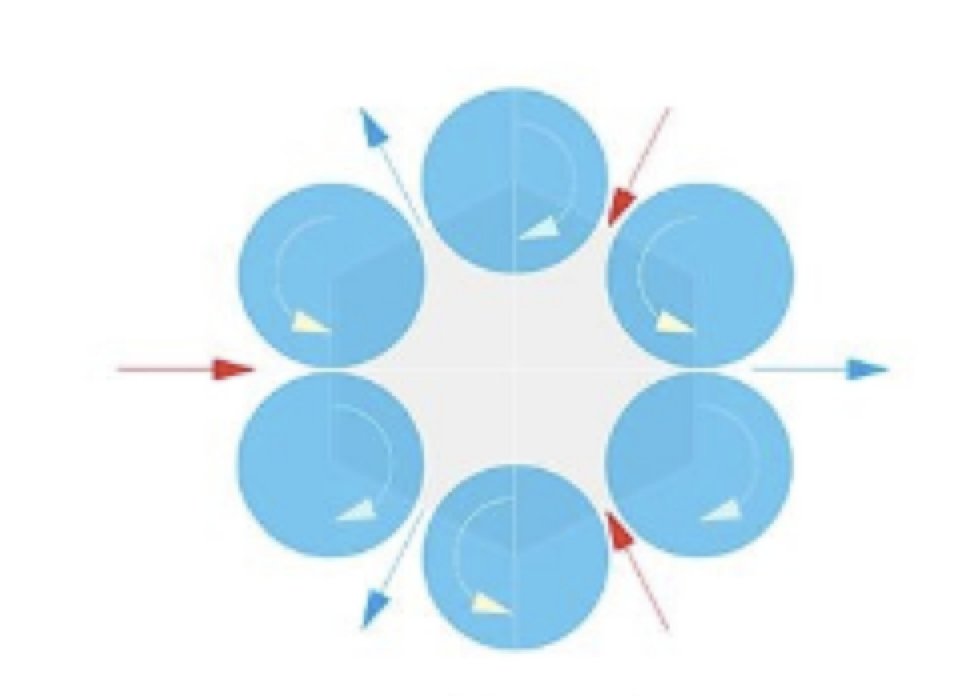

The M2, M4, and M5 propellers rotate clockwise, while the M1, M3, and M6 propellers rotate counterclockwise.

5.What are the differences between the overall layout and rotational direction of the propellers on the T16 and other conventional 6-rotor drones?

The layout and rotational direction of the propellers on the T16 create a more stable downward air-flow, which reduces the effect of upward mist, increases the spray width, and generates better sedimentation.

6.Can a single remote controller be used to control multiple T16 aircraft?

Yes.

7.How do I link the T16 aircraft to its remote controller?

Press and hold the power button for five seconds to begin linking the two devices.

8.Does the T16 have a separate GPS version and an RTK version?

The T16 is equipped with the RTK+GNSS Dual Redundancy System. It is not separated by version.

9.Does the T16 support the D-RTK 2?

Yes.

10.What are the improvements of the T16’s FPV camera compared to the MG-1P? Can FPV videos be saved?

The T16 provides clearer and smoother footage. FPV videos cannot be saved.

11.Is there any required assembly for the T16?

No. The T16 does not need to be assembled. After activation, it is ready for use.

12.Can the T16 airframe be folded?

Yes. The T16 can be quickly folded to 25% of its original size.

13.After I put batteries in the T16, will it power on automatically?

No. You must press and hold the power button on the battery to start the T16.

14.What is the difference between the remote controller of the T16, MG-1P, and Phantom 4 RTK? Are they compatible?

Although the T16, MG-1P, and Phantom 4 RTK remote controllers have different software, they have similar hardware. If you own an MG-1P or Phantom 4 RTK controller, you can update the software to make it compatible with the T16.

15.What is a safe distance to operate the T16 during takeoff and landing?

It is recommended that you keep a distance of at least 10 m.

SPRAY

1.What is the maximum volume of liquid the T16 spray tank can hold? Can the spray tank be replaced quickly?

The standard spray tank is 15 L, and the maximum volume is 16 L. Operators can replace the spray tank quickly.

2.What is the maximum spray rate of the T16?

When equipped with the XR11001VS nozzle, the T16 can spray at a rate of 3.6 L/min.

When equipped with the XR110015VS nozzle, it sprays at a rate of 4.8 L/min.

3.What is the pump pressure range of the T16?

2-4 kg/cm².

4.Are the pumps on the T16 and MG-1P cross-compatible?

No.

5.Are the nozzles and decompression valves on the T16 and MG-1P series cross-compatible?

Yes.

6.Does the T16 show residual liquids in real time?

Yes.

7.What is the purpose of the built-in NFC?

The built-in NFC ensures that the spray tank has been properly installed.

8.What are the advantages of the electromagnetic flowmeter on the T16?

The electromagnetic flowmeter is readily applicable and delivers high measurement accuracy, with a margin of error of less than ±2%.

Additionally, measurements are not affected by fluid density, viscosity, temperature, or pressure changes.

The electromagnetic flowmeter is resistant to corrosion and wear and is equipped with a stable measuring pipe.

This ensures that the flowmeter will be operable over a long period.

OBSTACLE AVOIDANCE

1.Is manual operation required when using the active obstacle circumvention feature on the T16?

No. The T16 can circumvent obstacles automatically without manual operation.

2.How does the T16 activate obstacle point cloud imaging?

Obstacle point cloud imaging operates through digital beam forming technology. The obstacle’s width, directional angle, and location can be sensed in real time so that the T16 can bypass it.

3.In what direction does the high-precision radar operate?

The radar functions in front of and behind the aircraft with a horizontal FOV of ±50° and a vertical FOV of 0°-10°.

4.Are the DBF Imaging Radar of the T16 and the high-precision radar of the MG-1P series cross-compatible?

No.

AI OPERATION PLANNING

1.How does 3D operation planning function on the T16?

After capturing orthographic images with the Phantom 4 RTK, use the DJI Terra, which supports Orchard Mode, to complete the 3D mapping of the field. Once the operation field is selected, the AI system will automatically identify object attributes such as crops and obstacles and automatically generate 3D operational routes. After these routes are downloaded, the T16 will then automatically start working.

2.What are the similarities and differences between the image collection for 3D operation planning on the T16 and that of the previous PC GS Pro?

Both capture orthographical images shot through the Phantom 4 series, but they create field-maps differently.

3.What can the DJI Terra identify while in Orchard Mode via AI recognition technology?

The DJI Terra can identify orchards, buildings, water surfaces, powerline poles, and the ground.

4.Can the T16 spray above trees that have an uneven layout and various heights?

Yes. The DJI Terra can recognize the location and height of fruit trees thanks to 3D mapping and AI recognition. The T16 only targets fruit trees and adjusts its flight altitude according to tree height to keep a constant distance above the trees.

BATTERY AND CHARGER

1.What are the differences between the batteries of the T16 and MG-1P?

The T16 battery can be replaced quickly, and it is equipped with higher voltage, a larger capacity, and a longer life-cycle. For your reference:

Agras T16 battery: 14S, 17,500 mAh, standard voltage 51.8V, 400 cycles.

Agras MG-1P battery: 12S, 12,000 mAh, standard voltage 44.4V, 200 cycles.

2.What is the difference between the T16 and MG-1P series chargers? Are they cross-compatible?

The T16 charger has a maximum output power of 2,600W, supports single-channel quick charging mode, and is capable of fully charging one battery in 20 minutes.

Additionally, the 2600W 4-Channel Intelligent Battery Charger can simultaneously charge four batteries in 80 minutes.

The T16’s charger can charge an MG-12000P battery, but the MG series charger cannot charge a T16 battery.

In the recent years, with the increasing use of plant protection drones for pesticide spraying operations in various countries and regions, the scope of applied crops has become wider, especially in areas where ground boom sprayers are difficult to access. Compared with traditional manual spraying operations, the plant protection drone used for low-altitude and low-volume pesticide application has higher operating efficiency and lower labor intensity; compared with manned large aviation aircraft, the cost is greatly reduced, the safety of pilots is guaranteed, and meet the needs of efficient agricultural economic development.

In particular, it is difficult to use ground machinery to carry out pesticide spraying operations for rice, mid-to-late corn, and agricultural economic crops grown in hills area which not only protects farmland from been crashing but also effectively responds to increasingly severe pest control tasks; To use drone Multi-spectral analysis of crops and accurate measurement of fields to achieve scientific management of real-time crops. At the same time, plant protection drones are used for pesticide spraying, separation of operators and machines, separation of operators and drugs, high efficiency and safety, and can be count on the entire growth period to use agriculture drones.

1. Environmental restrictions

It’s not restricted by the growing environment of crops, not restricted by tall plants and complicated geographical conditions.

2. Automatic obstacle avoidance and Three-dimensional navigation intelligent flight

The new DBF imaging radar equipped with DJI T16 is not affected by ambient light and dust, and can perceive and observe the environment all-weather. The radar supports terrain slope detection, and mountain slopes can also be simulated to fly. Promote. Its own digital two-way synthesis technology can realize three-dimensional point cloud imaging, which can effectively identify complex scenes during operations and realize automatic flight around obstacles.

The application of AI in the agricultural field has made DJI T16 once again at the forefront of global plant protection technology.

DJI’s agricultural intelligent solution adds a 3D modeling engine and an AI recognition engine. Facing the operating environment of cash crops such as orchards, with the PC Ground Station Professional Edition and the Phantom 4 RTK, the operator can smoothly realize the 3D reconstruction of the ground environment, AI intelligent scene recognition, 3D navigation planning, and autonomous flight.

With real-time image monitoring systems and night searchlights, operators can easily ensure the safety of equipment all-weather operation.

DJI T16 is also the first China plant protection drone equipped with three-dimensional aerial flight function.

3. Precise pesticide application

A DJI Agras T16 drone can operate 200 Acre a day, saving 50% of the pesticide. One remote control can remotely control 5 DJI Agras T16, so you can operate 1000 Acre in one day.

4. Safe and efficient

DJI plant protection drones are not affected by environmental factors, farmers don’t have to worry about damp land, they can apply pesticides at any time, and through ground remote control with GPS positioning system, spraying operators can operate remotely to avoid the danger of exposure to pesticides and improve the safety of spraying operations.

5. Drug quantity monitoring and automatic return

The T16 operation box also has two built-in liquid level gauges for liquid level detection, and the flow meter realizes accurate intelligent functions such as no medicine prompt and dressing point prompt. After reloading, the operation will continue at the breakpoint.

6. Newly developed power system and powerful thrust-to-weight ratio

On the T16, DJI’s engineers have equipped it with a newly developed power system. These 6 10015 motors can bring up to 81kg of total thrust. However, the standard takeoff weight of the T16 when fully loaded is only 39.5kg, and the thrust-to-weight ratio of the T16 motor reaches 2. The ultra-high thrust-to-weight ratio allows the T16 to reach a maximum operating flight speed of up to 7m/s, meeting the requirements for higher operating efficiency.

7. Large load and high efficiency

DJI engineers increased the maximum load of AgrasT16 to 16L and adopted finite element simulation design and carbon fiber composite material technology, which greatly reduced the weight of the whole machine while ensuring the strength, and the load factor reached 0.4, much higher than the industry average of 0.3-0.35. Increase the operating speed to 6m/s, the operating spray width to 6.5m, and the flow rate to 4.8L/min. Various aspects have been coordinated to improve, to give full play to the advantages of the 16L large load, and finally increase the overall efficiency by 67% to 25 Acre/hour.

8. Reduce drift

As we all know, the downward pressure wind field generated by the blades mainly accomplishes the sedimentation of the liquid from the air onto the crops. However, in actual operations, the drone is sprayed while flying, so liquid medicine will also be affected by the horizontal wind. If the downward pressure wind field generated by the blade is not strong enough, the liquid medicine will drift in the air instead of falling on the plants below. Therefore, in other words, blindly increasing the drone’s operating speed will reduce the operating effect; if If the droplets of the liquid medicine are too small, it will cause more serious problems of drift and rapid evaporation.

9. Strong pressure wind field, high efficiency

In response to these conditions, DJI engineers have made many response designs on T16. First, a large-size six-axis configuration and relatively small blades are used to obtain a larger wind field (spray range) and a stronger downward pressure wind field. Secondly, a pressure spray system is used. The pressure nozzle can provide the droplet with an initial downward velocity of about 2m/s, and the nozzle can excellently control the droplet.

10. Spraying system and Precise application

DJI Agras T16 is equipped with 4 new liquid pumps and 8 nozzles. Each liquid pump controls two nozzles separately. The flow control range is 1.28L/min and the maximum is 4.8L/min, which is not only easy to meet The operation requirements of conventional crops such as rice and wheat can also meet the operation requirements of complex and large-flow scenarios such as fruit trees, which extends the scope of T16.

At the same time, T16 has a built-in new long-range electromagnetic flow meter, the measurement error of the full range is less than 2%, such as spraying a 500ml bottle of mineral water in normal operation, and the final measurement error will not exceed the water volume of a bottle cap. In practical applications, it will effectively improve the accuracy of the drug dosage for T16 farmland spraying operations.

At a working height of 2m, the spray width can reach 6.5 meters, an increase of 44% over the previous generation.

With the blessing of many black technologies, DJI T16 has achieved an ultra-high spraying efficiency of 25 acre per hour, which is 67% higher than the previous generation, far exceeding the industry average.

Note: The operating altitude can be set to 0.5M-2M, and the flying altitude can be up to 80 meters, but the default setting is within 30 meters.

11. Spraying effect

Agras T16 has high efficiency of helicopter operation and good spraying effect; at the same time, DJI’s second-generation Agras T16 plant protection drone has a flexible speed change function, which can fly directly from zero to normal speed. It works well under low-speed conditions. The fog drop coverage, especially the strong downward swirling airflow generated by the rotor, can reduce the scattering of fog particles, and at the same time, the upward airflow generated by the downward swirling airflow can directly deposit pesticide droplets on the front and back of the plants’ leaves.

12. Gem six-axis design

Senior pilots know that conventional positive six-axis drone blades are arranged in clockwise and counterclockwise rotation alternately. This has no adverse effects on ordinary drones, but For plant protection drones, this layout will raise the wind field at the front left and rear left of the drone, which will affect the uniform distribution of fog droplets and the effect of the strong settlement. The original gem-shaped aerodynamic layout of DJI T16, by adjusting the position of the motor and the direction of rotation of the blades, recovers and stabilizes the originally rising wind and enhances the settlement effect. At the same time, the wind on the left side of the fuselage is dissipated symmetrically with the right side to increase the spray range, so that the airflow of the T16 wind field is more stable. With the optimized nozzle position, the droplet settlement effect has been significantly improved. In the faster-operating speed, it still maintains good operating results.

DJI Gem Six-axis Design

Traditional Six-axis Design

13. Atomization effect

The spray system of the plant protection drone is mainly composed of a medicine box, an atomization device, a liquid pump and its accessories (voltage regulator and regulator), etc. The pesticide liquid is controlled from the medicine under the pressure of the liquid pump. The box reaches the nozzle through the pipeline, where it is atomized by the hydraulic nozzle or centrifugal nozzle and sprayed on the target crop.

14. Single plant operation

The hovering function of the Agras T16 enables it to spray a single plant.

15. whole set of drone solution for agriculture

DJI Agriculture started relatively early in the industry-level products. Since entering the market in 2016, it has launched the second-generation spraying drone T16 for crop monitoring, consulting, and irrigation, high precision mapping management and spraying systems, P4 multi-spectral UAV and Phantom 4RTK. And the latest drone orchard mode that Agras T16 has.

16.Reduce losses on crops

Another significant advantage of DJI plant protection drones is that they can avoid the economic losses caused by running/rolling on traditional ground sprayers; according to the estimation, the crop loss ratio will be around 2%-5%. At the same time, it can even energy-saving water and medicine, which is more conducive to environmental protection.

17. Operation effect

The application of plant protection drones is to improve the operation effect and reduce the production cost. It is necessary to avoid re-spray or miss spray, save pesticides, and reduce costs. This has higher requirements for precise flight and precise spraying. DJI uses the Phantom 4 RTK system to control the operation accuracy within 1cm+1ppm (RTK Horizontal Positioning Accuracy)1.5cm+1ppm (RTK Vertical Positioning Accuracy)

18. Safety factor

Especially for rotorcraft, when the engine fails, using the rotation of the rotor, through the correct operation of the driver, the landing speed of the forced landing can be close to 0, and the plant protection drone can increase the flight by slowing down and responding quickly Security and predictability. Because the pilot operates from a long distance, the safety factor is 100%.

19. Folding design

The size of T16 when unfolded is 2520mm×2212 mm×720 mm, and when folded, it is only 1100mm×570 mm×723 mm. Its unique folding method reduces the space occupied by 75% after folding, and the storage is very friendly, making it easier and more convenient for the plant protection team to transport.

20. Modular design

T16 reshapes the structure of the whole machine. The avionics module, spray system, ESC, and other components adopt a modular design, which supports quick replacement. At the same time, the wiring depth of the whole machine is simplified, no welding is required, and routine maintenance is more convenient, and time-consuming will be greatly shortened. With the support of these designs, the maintenance and replacement of parts of the T16 are actually like playing Lego blocks.

21. DJI T16 installed a brand new smart battery. The battery adopts a newly optimized cell formula and heat dissipation design, and the number of safe cycles can reach 400 times, which is about double the previous generation product, greatly reducing the cost of battery loss during operation. The new battery is equipped with a brand new 4 channel 2600W charger. In single channel fast charge mode, a battery can be fully charged in 20 minutes, and the charging speed is increased by 50%.

Both the battery and the operation box of DJI T16 support quick plug-in function, and the battery and operation box can be replaced in just a few seconds.

22. Water pump. DJI T16 adopts a brand-new composite water pump, which is corrosion-resistant, large flow rate, and life-span improvement of the previous generation product by 60%. For efficiency, DJI T16 also uses a brand-new electromagnetic flowmeter, measuring mechanical flowmeter, the accuracy is increased by 50%. Both the battery and the operation box of DJI T16 support quick plug-in function, and the battery and operation box can be replaced in just a few seconds.

23. Protection level. In addition, the protection level of core modules such as DJI T16’s avionics board and ESC has reached IP67, and the size design makes full use of each key part, which also greatly improves the maintenance efficiency of the whole machine.

More important is:

1- DJI is currently the only company in the industry with wind field analysis and design capabilities.

2- DJI has high-quality technology and R&D team to ensure effective solutions and reliable performance of agricultural drones.

3- DJI is currently the only drone company that provides comprehensive solutions for agriculture.

COME AND TALK WITH OUR TECHNICAL EXPERT

CHOOSE THE RIGHT DRONES FOR YOUR FARM AND INDUSTRY TODAY

We will work with you to explore and develop your business and you will be glad to see how drone technology can change your field and benefit your life.